Crane Safety

This platform is dedicated to providing essential information and resources to ensure the safety and efficiency of all crane and hoist operations on our campus. Explore our guidelines, training materials, and inspection protocols as we work together to prioritize safety on campus for students, faculty, and staff.

Example of a Jib Crane on ISU’s Campus (located at the EAMES Complex)

The purpose of the Crane Safety Program is to establish safe work practices and inspection procedures for the operators of electric, manual, and hydraulic overhead and gantry cranes. In addition, making sure the Idaho State University students, staff, and faculty are protected from potential hazards associated with the movement of equipment and materials using a crane, hoist, and other related equipment.

- Gantry Crane: A type of overhead crane with supported by freestanding legs that move on wheels or along a track or rail system

- Jib Crane: A crane with an operating arm that extends horizontally from the crane.

- Manual Chain Hoist: A crane designed to lift and move heavy loads by means of a rope or chain with the force of the arms

- Electric Chain Hoist: An industrial material handling device that uses electricity to lift and lower large, heavy-duty objects

- Bridge Crane: A type of crane that includes two overhead runways built into the building's support structure.

- Monorail Systems: A type of crane that continuously runs on fixed, overhead track on which trolleys travel while carrying loads

- Hydraulic Engine Lift/Cherry Picker: A robust lifting device featuring a base frame, an adjustable boom, a hydraulic cylinder, a pump and control system, and a lifting attachment.

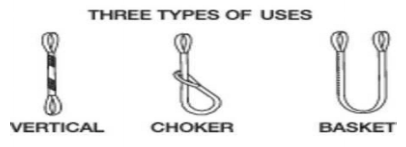

Vertical sling: configuration is the simplest and used the most. In this arrangement, the sling is attached to the load at a single point and lifted vertically. Vertical slings are typically used when the load is stable and can be safely lifted without tilting or swinging. Examples include lifting heavy machinery or containers.

Basket sling: configuration involves attaching the sling to the load at two points, creating a cradle-like support. This configuration is used when the load is bulky or irregularly shaped, and there is a need to distribute the load weight evenly. Basket slings are commonly used for lifting pipes, beams, or other long objects.

Choker sling: configuration is designed to grip cylindrical loads like pipes, logs, or barrels. The sling is wrapped around the load and then passed through an end attachment, creating a choking effect. This configuration provides a secure grip on the load, preventing it from slipping or rolling during lifting.

Training:

- One-time 1-hour awareness training (Standard Operating Procedure)

Inspections:

- Frequent inspection - Daily to monthly intervals.

- Periodic inspection - 1 to 12-month intervals.

-338x297.JPG)